Overview

CASoft is an Expert System for MCAE (Mechanical Computer Aided Engineering) applicable to large

scale computational models of:

Thermal, Mechanical Analysis

Structural Analysis and Design.

CASoft is based on a new computational engine that outruns the state-of- the art Finite Element engines (FEM)

by a factor 100, both for computational speed and for model size (see Benchmarks). CASoft incorporates

a Fractal Model builder and a Graphic User Interface: they operate online with the equation solver.

The computational power of CASoft comes from innovations that sweep all the facets of computation : mathematical algorithms,

data buffering, grid modeling, graphic rendering. CASoft is written in C++ Language, embedded in the

environment of MFC (Microsoft Foundation Class) . No writing on disk, no virtual memory: CASoft runs entirely on RAM.

The power of the CASoft engine, when running current models of Analysis, leads to completing the jobs in real time,

thus setting a new mode of man-machine interaction.

For instance: a large thermo-mechanical model (1e5 variables) runs within 1 min; during the run, the user receives online the graphic

rendering of all the basic results. Thus he can take decisions in real time, and/or perform extensive parametric

analyses of the model.

CASoft adds a new productivity to mechanical analysis, and a new throughput from it.

The power of the CASoft engine has also extended the horizon of MCAE into new applications, insofar not accessible,

thus making the code an Expert System for design:

Virtual Welding: the User can ‘design’ the weld parameters that produce welded joints of sure Quality both fo

distortion and for joint strength.

See Project WAM

(Ref. [1]).

The Quality of the welded joints has a major relevance for structural design. Indeed, the joints welded according

to the Protocol of Quality, show an extended ductile behavior, reaching an ultimate load far higher than the service load.

Structural Optimization : CASoft computes the least weight stiffness configuration for a framed structure by applying

iterations to structural Analysis. While designing, the user needs not input the cross-sections of all the members:

they will be computed internally.

Design-by-Analysis: the safety factors computed by the Normative Codes for welded joints usually add a stiff

penalty to the weight of the structure. With CASoft, the know-how acquired from Virtual Welding is collected

into an internal data base that links the weld parameters to the applicable safety factors. The data base is

used internally to adjust the optimum structural configuration.

In

Project MASC

(Ref. [7]), the weld parameters will be written into a data file used to drive welding robots. The project is meant to

close the loop design-manifacture, thus entering into the class of Projects INDUSTRY 4.0

The copyright of the CASoft Software is owned by the homonymous company.

The code is authored by Dr. Aldo Cella, a pioneer of Finite Elements.

See CV

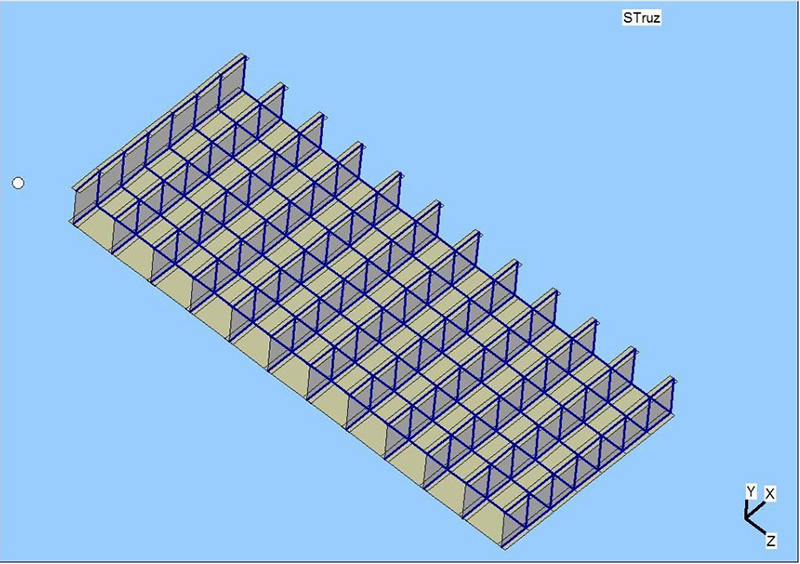

Fig. 1 - Model of a framed deck structure.

Fig. 1 - Model of a framed deck structure.

The viewpoint is from below to show the grid of beams (in blue)

Notice that the grid is made of full-sized members: no approximating

elements to fill the members because the Algorithm computes the exact solution.